Approach

The location is extremely important for the technical performance of the solar lighting columns and thus the choice of the type needed. There are some indicators that are always important to check:

This site uses cookies that need consent.

The location is extremely important for the technical performance of the solar lighting columns and thus the choice of the type needed. There are some indicators that are always important to check:

The location is extremely important for the technical performance of the solar lighting columns and thus the choice of the type needed. There are some indicators that are always important to check:

The location is extremely important for the performance of the solar lighting columns and thus the choice of the type needed. Some indicators we always check:

Shading: Trees or buildings near the solar columns may cause shadows and influence the performance negatively. Try to bypass shading as much as possible.

Aesthetic choice: If the illumination is needed for a residential area or park, one might choose for less height or another type of luminaire (Anne), and consequently choose for an increase of the units needed.

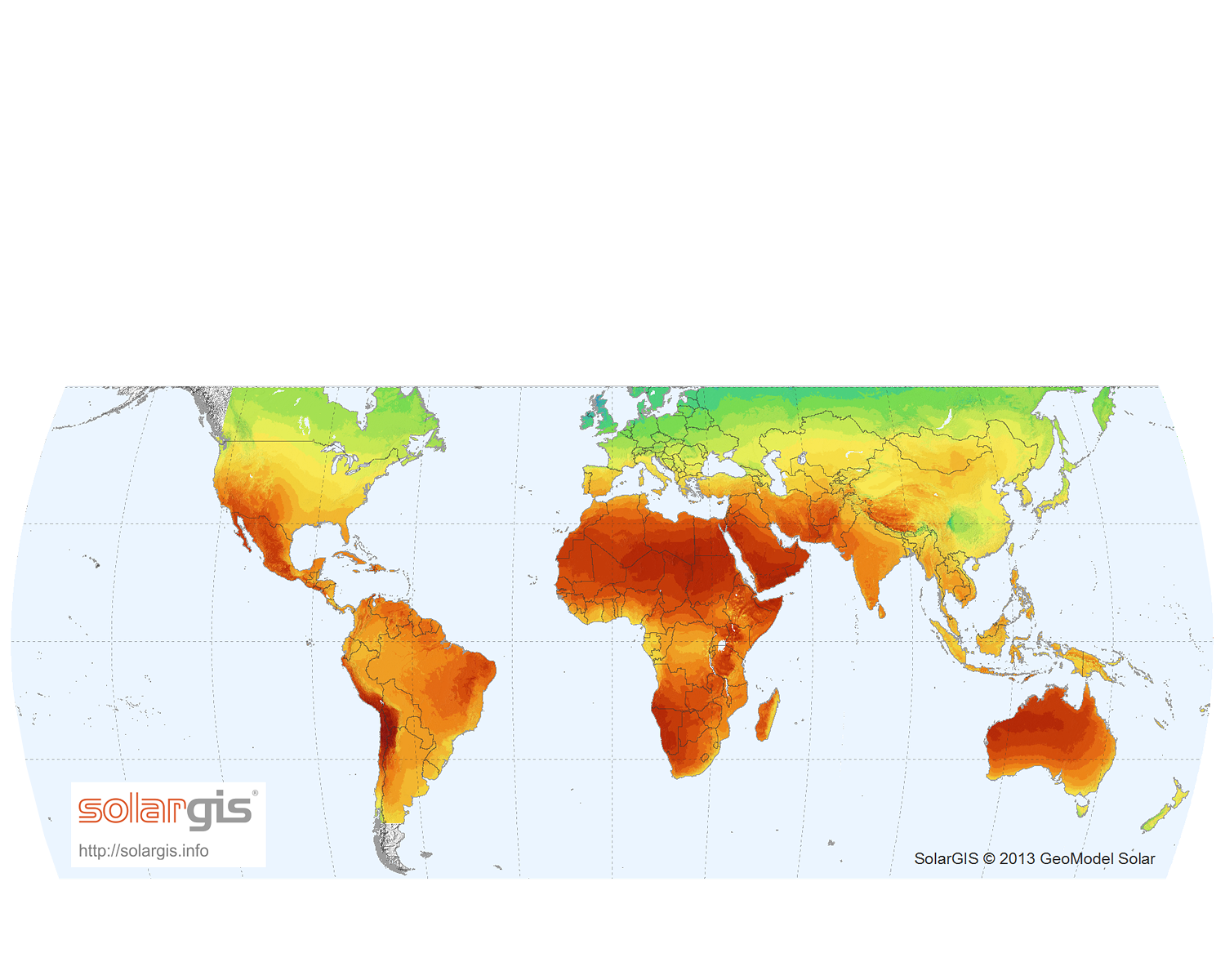

Latitude: Very significant is the latitude. It determines the sunirradiation and thus the expected energy generation. Mostly, we ask our (potential) customers for a Google Maps-location to determine the expected sunirradiation based on historic data.

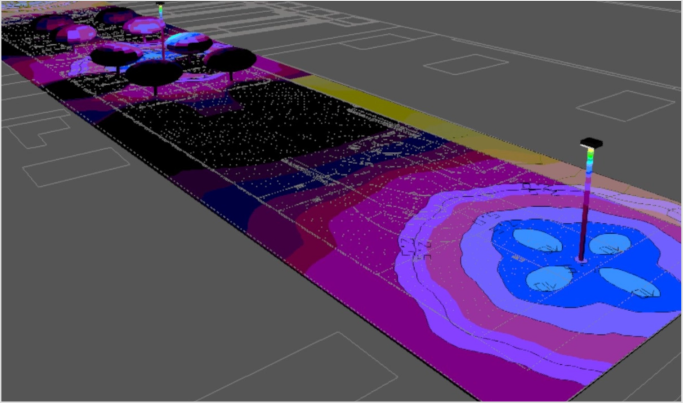

The location will determine the type of solar lighting column. Next step is to determine the quantity needed for a project to be illuminated accordingly. Therefore, we will focus on the lighting classifications and make a quick photometric study (in DIALux, conforming to EN13201:2015). Based on our luminaires Alexia and Anne, we will determine the most effective intermediate distance of the columns and the most economic lighting design for our (potential) customer.

Following the planning phase, we transition into production. With everything in place, we are ready to prepare your order. Our aim is to deliver high-quality products that meet the highest standards. To achieve this, we've gathered a network of partners to ensure flexibility and the ability to produce swiftly. Quality control is a crucial step in our process, verified in Oss, at SPIRIT's premises, during the production phase to ensure every product meets our stringent standards. Everything is tailored to meet the specific needs of our customers. SPIRIT operates with minimal stock, emphasizing that each product is specially made for our customers.

Upon the arrival of the columns at the installation site, the accompanying instructions simplify the setup process: connect the luminaire, erect the column, and it's ready for immediate use. The columns are securely packaged to protect the finish and solar panels from damage. To install, first dismantle the packaging, then use a mobile crane with a sling attached to the top's eyebolt to lift and vertically position the columns on their foundation. Secure the column by tightening the four bolts on the foundation for a stable installation.

Activating the system is straightforward—simply connect the battery connectors to the control unit, and the system will begin charging. To enable the communication platform (whether via Bluetooth or LoRa), activation through the SPIRIT Supervisor app is required, ensuring seamless integration and operation from the outset.

The system's status can be efficiently monitored both visually and digitally for comprehensive inspection. We recommend regular checks of the columns for any signs of failure, damage, or contamination. The SPIRIT supervisor app facilitates inspection of technical functionality via Bluetooth, while direct access through the control room is available for systems utilizing LoRa. The SPIRIT control room serves as a centralized hub where all data regarding the columns' current state are aggregated, allowing for detailed monitoring of their condition and performance.

Regarding maintenance, the necessity for deep cleaning will vary based on the desired aesthetic standards. Based on our experience, such extensive cleaning measures are generally not required to maintain optimal functionality. The vertical integration of the solar panels is designed to allow rainwater to naturally cleanse away any debris or contaminants, further simplifying maintenance efforts.